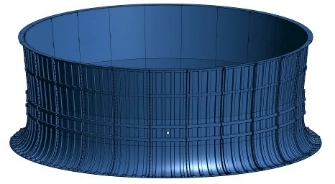

Fan stacks

We produce 5 types of fan stacks, which are adapted to the structure of the roof of the cooling tower and, above all, to the fans working in them. Our fan stacks are made 100% in the European Union according to the strictest quality standards. Thanks to the use of a double-shell fan stack structure, there is no vibration or material erosion.

HOW TO CHOOSE THE FAN STACK?

It often happens that the selection of an appropriate fan stack is marginalized. An improperly selected fan stack affects the operation of the entire cooling tower. It is the fan stack that determines the power consumption, pressure recovery or additional costs in the case of modernization.Buying a fan stack from a manufacturer that also does not work in the impeller market may result in the complete fan not working optimally. Wentech fans propose fan stacks ideally suited for a given model of the fan as well as the model of a cooling tower.

FRP Fan stack advantages

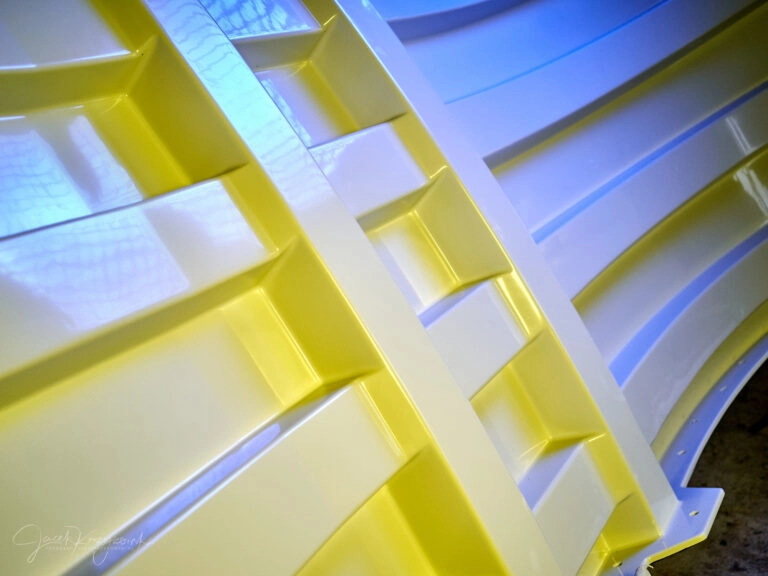

Double-coat structure, internal and external surfaces are smooth

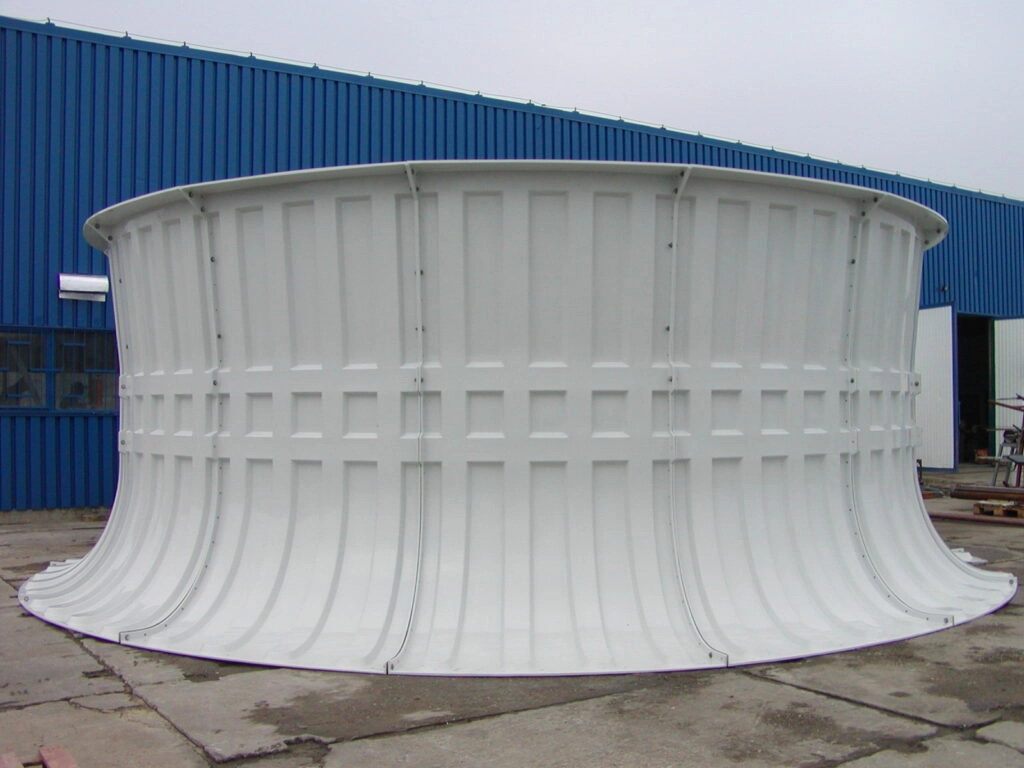

Every segment is identical – easy assembly

Low weight – in comparison with steel fan stacks

Special ribs secures high stiffness and protects from vibrations

Single layer v double layer FRP fan stacks

Smooth internal layer of the doublelayer fan stack

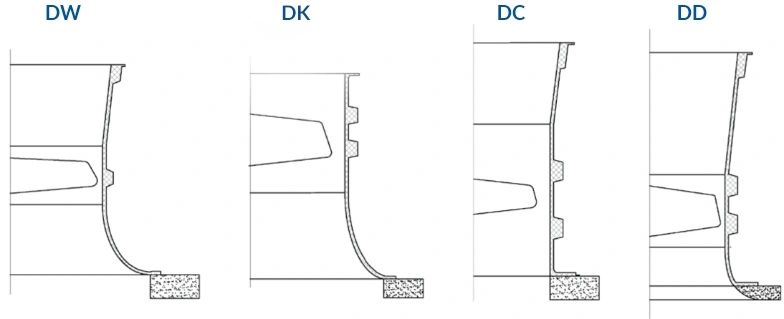

Fan stacks shapes

Fan housings are another key product offered by WENTECH. The purpose of the diffuser is to properly shape the airflow through the fan in order to achieve optimal flow parameters and ensure the highest possible efficiency of the system.

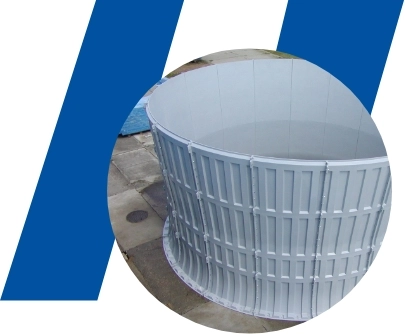

Fan stack project examples

Basic parameters

- Fibreglass reinforced polyester execution

- Protected with UV-resistant gelcoat

- Special ribs secure high stiffness and protects from vibrations

- High execution standard facilitates central alignment of the impeller and setting the optimum blade tip clearance

- Segmented design – easy transport and quick assembly on ground level or cooling tower’s roof

- Low weight – in comparison with steel fan stacks

- Fasteners made of SS304 stainless steel

- Standard operational temperature: -40°C do +65°C

- Standard colour: RAL 7035 or RAL 5015. Any RAL colour available on demand.

Optional equipment

- Access door,

- Porthole,

- Repair and touch-up kit,

- Stainless steel fasteners,

- Lifting eye

Optional equipment example

Quality control process

The long-term operation of our products in customer cooling towers is based on efficient and extremely strict quality control. A 5-step process is carried out for each element at a particular stage of its production, from production, through finishing to logistic activities. The controlled element receives a separate, standardized according to the standard. ISO 9001: 2015 quality card, kept indefinitely in our archive.The individual stages of the process are picked up by a production employee, an employee with the rank of a master and an independent specialist of the quality control department. Each segment of the product must undergo a verification consisting of over 50 control elements, and failure to meet at least one of the requirements results in failure to assent to acceptance

We check, among others the presence of all kinds of scratches, blisters, production damage or cracks. Even the smallest defect is repaired and the element must undergo another quality control to be put into service. The final stage of the process is to verify that the products have not been damaged during packaging, as well as whether its method and material are appropriate. Our clients receive a certificate for each element of the product, which confirms the passage of strict quality control.

Every element, every product, at every stage of production undergoes detailed quality control!

Strict quality control = premium quality

Process description

1. Inspection of the item during the main production process

The unfinished element is inspected for surface damage, weighed, and compliance with the subject of the contract is measured.2. Element inspection during the finishing process

During finishing, each ground element is verified for accuracy. After cleaning and polishing, the surface of the product is checked for possible defects or damage.3. Control of the element during the gelcoat and topcoat application process

The element must be 100% covered with an uninterrupted, damage-free protective layer. While applying the gelcoat and topcoat, the thickness of both layers is also controlled.4. Control of the heating process

The records from the burner register are analyzed. The specialist checks whether the element has been heated in the optimum temperature for a long time.5. Control by the logistics department

The element is fully inspected, the packaging method is verified and whether any detected defects have been removed.

Special design

High temperature conditions +120°C

Hub elements made of stainless steel SS304 or SS316

Reinforced execution, for harsh operation conditions

Self extinguishing execution

Acid resistant

Antistatic