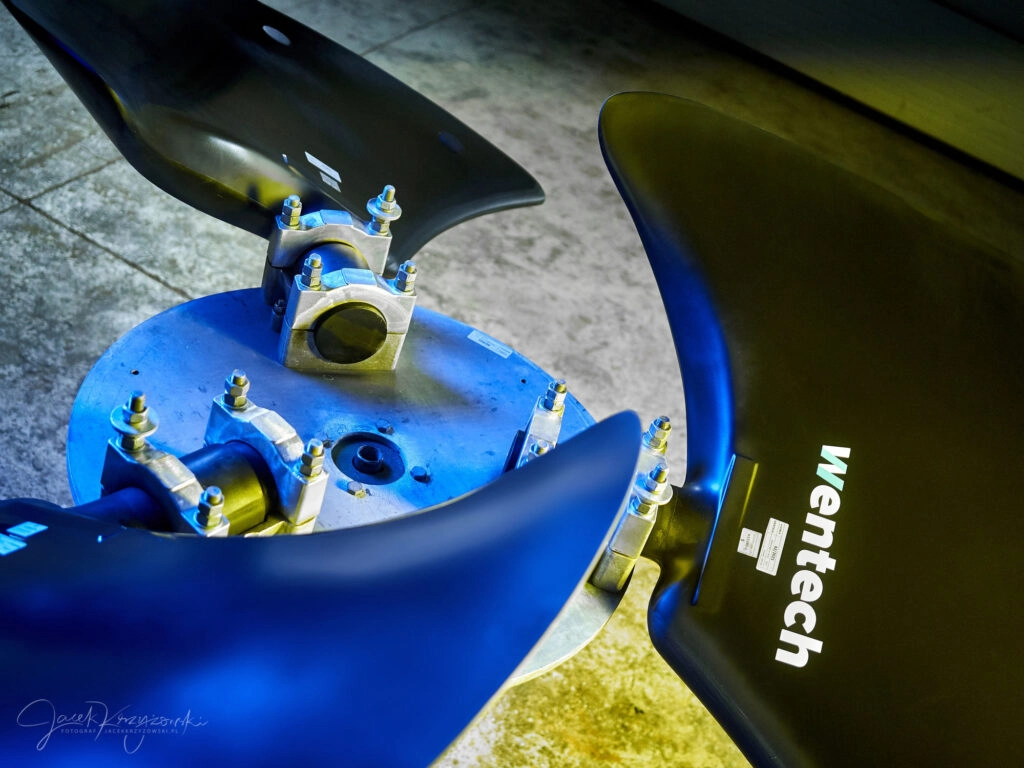

Fan impellers

The largest range of WENTECH production are impellers. Designed for axial fans used in cooling towers and dry air coolers, they ensure failure-free operation in the harshest environmental conditions.

Thanks to our R&D, we have created the quietest fan blade profile on the market Model 15.

It is the most effective solution in the fight to silence cooling towers while maintaining flow parameters.

Thanks to our R&D, we have created the quietest fan blade profile on the market Model 15.

It is the most effective solution in the fight to silence cooling towers while maintaining flow parameters.

Our fans are 100% manufactured in the European Union from certified raw materials in accordance with the know-how developed over 25 years.

The result is failure-free operation of the fan throughout the life cycle of the cooling tower.

The result is failure-free operation of the fan throughout the life cycle of the cooling tower.

- 27 years of experience

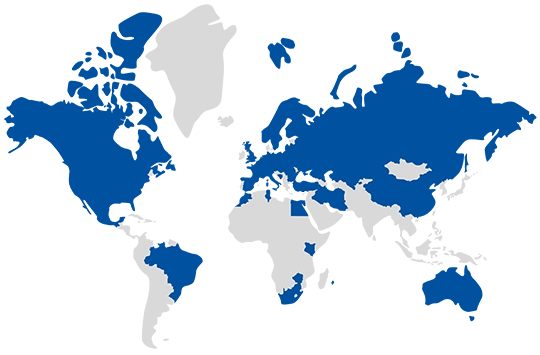

- 42 countries where our fan impellers have proven themselves

- 100% functioning during warranty

Advantages of our solutions

Blades made of fiberglass reinforced polyester

Smooth surface protected by UV resistant gelcoat

Protected blade leading edge

Standard operational temperature: – 40 to +65°C

Special execution

High temperature conditions +120°

Hub elements made of stainless steel SS304 or SS316

Reinforced execution, for harsh operation conditions

Self extinguishing execution

Acid resistant

Antistatic

Fan impellers around the world

Quality control process

The long-term operation of our products in customer cooling towers is based on efficient and extremely strict quality control. A 5-step process is carried out for each element at a particular stage of its production, from production, through finishing to logistic activities. The controlled element receives a separate, standardized according to the standard. ISO 9001: 2015 quality card, kept indefinitely in our archive.The individual stages of the process are picked up by a production employee, an employee with the rank of a master and an independent specialist of the quality control department. Each segment of the product must undergo a verification consisting of over 50 control elements, and failure to meet at least one of the requirements results in failure to assent to acceptance

We check, among others the presence of all kinds of scratches, blisters, production damage or cracks. Even the smallest defect is repaired and the element must undergo another quality control to be put into service. The final stage of the process is to verify that the products have not been damaged during packaging, as well as whether its method and material are appropriate. Our clients receive a certificate for each element of the product, which confirms the passage of strict quality control.

Every element, every product, at every stage of production undergoes detailed quality control!